Contract manufacturing of electronics

Production of electronics of any complexity and volume – from prototypes to serial ones at Morion PJSC.

Production of electronics of any complexity and volume – from prototypes to serial ones. PJSC “Morion” provides services:

- automatic double-sided and manual installation of printed circuit boards;

- setting up radio-electronic equipment; optical and electronic testing;

- repair of electronic equipment products (including installation, dismantling of BGA housings and restoration of ball leads);

- product testing: climatic, mechanical, electrical;

- application of moisture-proof coatings, incl. washing assembled units in an ultrasonic bath;

- production and marking of cables and harnesses;

- laser marking, A2 format;

- production of labels on a thermal transfer printer;

- production and assembly of blocks, telecommunication cabinets; provision of measuring instruments for rent.

The high quality required for manufactured products is ensured by the use in production of modern technologies for assembly, installation, quality control, means of testing equipment and its components, as well as through the introduction at Morion PJSC of standards adapted to the requirements of IPC and JEDEC standards. The quality of solder connections and printed circuit board assembly is controlled for compliance with the IPC-A-610C, Class 3 standard. Acceptance of assembly and soldering of electronic components complies with IPC-A-610D, Class 3.

Part of the equipment:

- two surface mount lines Universal and Samsung with multi-zone ERSA reflow ovens and an inert atmosphere soldering system – capacity of 60,000 and 35,000 components per hour;

- Soltec Delta Wave double wave soldering line;

- selective soldering installations ERSA and ZSW;

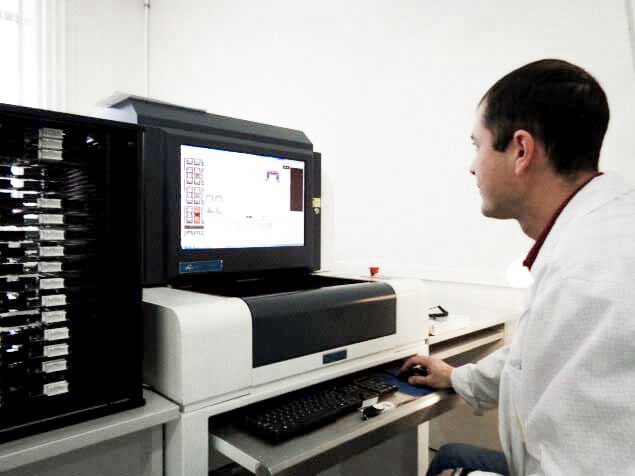

- automatic optical inspection ALD625;

- installation of jet cleaning of printed circuit boards Super Swash III;

- Swash stencil washing installation; screen printing machine DEK 03IX;

- special installation equipment ERSA, PACE, WELLER;

- system of selective application of moisture-proof coatings SL-940E;

- visual monitoring installation (stereoscope, television camera, monitor) DIMA SMIS-50ZT, Mantis;

- installation of separation of group blanks;

- ultrasonic cleaning bath ELMAT 700/N;

- equipment for molding pin components. installation of wire stripping EcoStrip 9300;

- cable line tester SYNOR 5000-P;

- thermal transfer printers Zebra and Brady for the production of self-adhesive labels with printed inscriptions.

Technical characteristics of surface mount lines:

- number of installed components 60,000 and 35,000 pcs./hour;

- the number of boards assembled per shift on one line is up to 600;

- board size – from 50×50 to 460×510 mm; board thickness from 0.38 to 4.2 mm;

- accuracy class – 5;

- element installation accuracy ±50 µm at 5σ;

- lead pitch of surface-mounted components (SMD) – from 0.1 mm; contact pad area size – from 0.2×0.2 mm;

- single-sided and double-sided installation with or without stencils, with installation in one pass along the line of up to 120 nominal chip components and up to 50 standard sizes of microcircuit packages;

- SMD package types: BGA, mBGA, SOIC, QFP, SOT, QFN, PLCC, CHIP (from 0201);

- installation of pin components;

- lead and lead-free soldering technology;

- control of ambient temperature and air humidity;

- optical quality control of soldering; installation of components from standard coils, canisters, pallets.

To place an order for installation of printed circuit boards, you must provide:

- board source file *.pcb PCAD, Protel; group blank file (if the boards are multiplied);

- technological files for ordering a printed circuit board in Gerber RS-274X (CAM-350) format;

- assembly drawing or wiring diagram in AutoCAD or Adobe Reader format;

- specification or list of positional designations of elements and their corresponding denominations in Microsoft Office format;

- file for the installer of surface-mounted components (Pick & Place); additional requirements for mounting the board.

If you place an order for the manufacture and installation of a printed circuit board of your design, our specialists will help you with adapting the board routing topology and placing components for automated installation, including obtaining Gerber files for the manufacture of a printed circuit board and stencil.

Contacts:

Director of operations

Polygalov Sergey Petrovich

tel.: + 7 (342) 206-59-31

e-mail: polygalovsp@morion.ru

Chief specialist for technological support of production

Tunev Dmitry Gennadievich

tel.: +7 (342) 207-59-87

e-mail: TunevDG@morion.ru